Efficient production through a clever use of automation

FOBIS® Line management

FOBIS® Line management is the solution for production line control. The following can be controlled using FOBIS® line management:

- Goods flow

- PLC (management or management and control)

- Quality

- OEE

- Progress monitoring

Control management

FOBIS® maintains the recipes including the associated process parameters. A touch terminal is installed at the line, which is used to start the order. This terminal displays all information relevant to the operator. When starting the order, there could also be a command to the PLC control. This also controls the correct process parameters. There is an option for mandatory quality checks by the operator prior to starting the process.

Checks

Checks

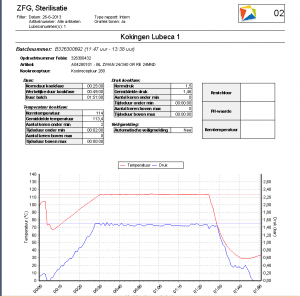

The process data are checked during the process. An alarm can be generated in case of deviations. At the same time, all process data are stored historically; the flow of the process data can also be viewed afterwards. The example here is a report that includes the cooking batch data per pallet (goods flow).

Would you like to know more about FOBIS® line management?

Contact us