Expanding production?

FOPRO ® Transport control

The RBK transport controls originate in the slaughterhouse technology. RBK has various technologies available for transporting carcasses or partial carcasses of pigs, cattle ot sheep, that can be utilised depending on the product or function to be transported. These can be divided into the following groups:

Conveyor systems

Conveyor systems are most commonly used to ensure efficient and reliable transport.

These can be controlled by RBK by way of a customised control system. Synchronisation of several conveyors is ‘child’s play’.

Storage systems

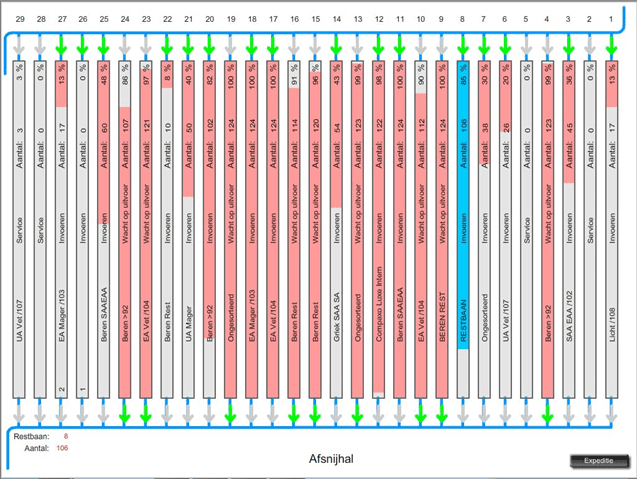

As well as the automation of transport conveyors, RBK also supplies the control mechanism of conveyor systems that are specifically used for automated storage of carcasses or product in a cold store. Whereas transport conveyors usually operate on a continuous basis, the storage systems are characterised by a discontinuous process where the carcasses move along a certain distance at intervals. Transport conveyor systems and storage systems function perfectly well in a fully automated cold store. We also visualise, in combination with FOBIS®, the occupancy and the statuses of the tracks, allowing you to be up to date and therefore allocate the tracks in the most efficient manner.

Return systems

Wherever carcasses are transported from a slaughter hall to a cold store, cutting hall or shipping area, the slaughter hooks or spacers have to be cleaned and returned to the slaughter hall afterwards. The return system has its own control system that can be combined with the control system of a slaughter line. RBK can also provide the control functions of these return systems.

Would you like to know more about FOPRO® transport control?

Contact us